Automatic Taping Equipment

V-TEK’s lineup of automatic and high=speed taping equipment.

TM-400

The TM-400 series offers a simple and compact automated taping system in a table-top machine. Each of the series options specializes in a particular input—tube, tray, or open module—for OEM use. A 2D vision over tape verification system ensures components are correctly oriented. Set up is simple via touch screen interface, minimizing interaction to ensure fast, dependable and accurate operations.

-

Production output: Carrier tape pitch 2-144mm, 8-72mm width

Minimum part sizes: 2mm x 2mm or 0805 (operator/settings dependent)

Dimensions: H 39.5" (100cm) x W 53" (135cm) x D 35.5" (90cm), Weight 217 lbs (98.5 kg)

Power required: 120/240 VAC, 50/60 Hz AC, Air 5 SCFM at 85 PSI

Ability to rotate components +/- 90° or 180°

Placement speed: UPH 2000-3500 (device dependent)

-

Touch screen operator interface

Software controlled advance movement of carrier tape

Universal adjustable heat and PSA sealer

Automatic jam in track and low cover tape detection sensors

2D vision inspection

-

401: Tube input - Width 0.316"-1.51" (8.38mm), Thickness 0.15"=0.465" (3.8-11.8mm)

403: Tray input - JEDEC Trays

Floor stand available for all models

As an equipment manufacturer, V-TEK collaborates with major tape and reel companies to ensure their products are compatible with ours. As part of a refined supply chain, V-TEK is your single source of fully qualified consumable products.

TM-500

The TM-500 is a customizable multiple-input pick-and-place, test, inspection, and taping machine designed for high mix-low volume production environments. The flexibility of multiple inputs reduces the need for additional machines, simplifying and speeding setup and operations to deliver a fast return on investment. Options for testing, and inspection, as well as 2D and 3D vision systems, provide maximum flexibility, reporting, and traceability functions. A touchscreen interface minimizes setup and operator intervention for fast and easy functioning.

-

Production output: 8-56mm width

Minimum part sizes: 2mm x 2mm or 0805 (operator/settings dependent)

Dimensions: H 66" (100cm) x W 44" (65" with monitor arm fully extended) x D 36" (64" with input and take up reels), Weight 1200 lbs (545 kg)

Power required: 240 VAC, 50-60 Hz AC, Air 5 SCFM at 85 PSI

Placement speed: UPH 2000-4500 (device dependent)

-

Automated component handler with tray, tube, bowl or tape input options

Reject to tray or bulk of bin sort

Industrial PC with touch screen operator interface

*Job configuration

*Manual / Automatic leader / trailer

*Lot reporting

*Vision inspection display and results reporting

*Password protection

-

Contact our sales and engineering team to customize a system for your application

TM-600

The TM-600 is a tabletop automatic system that delivers high throughput at an economical price. This high-value system is capable of processing bowl-fed components at a rate of up to 8000 uph thanks to the all-new dual-head rotating pick-head design and taper features. Able to handle parts down to 0805 and up to 1.75”, the TM-600 is the perfect low to mid-volume production machine to get components into tape and reel quickly, efficiently, and affordably.

-

Machine footprint: 65” Wide x 35” Depth x 35” Height

240v @2A or 120V @4A power supply single phase

80 to 100psi @ 5SCFM Air supply

-

Bowl Input

Max Part Size: 1.75”x1.75”x.250”

Min Part Size: .080”x.050”

Up to 8,000 UPH (Device Dependent)

Adjustable carrier tape output from 8mm-72mm width and a pitch of 2mm to 144mm

PSA or Heat Seal cover tape capable

Jam in track, low cover tape, and empty pocket detection sensors

Job configuration & setup

Sealer dwell adjustment

Pick and place dwell adjustment

-

Optional reject bin can be added for some applications

Camera over Tape for Pin1 orientation

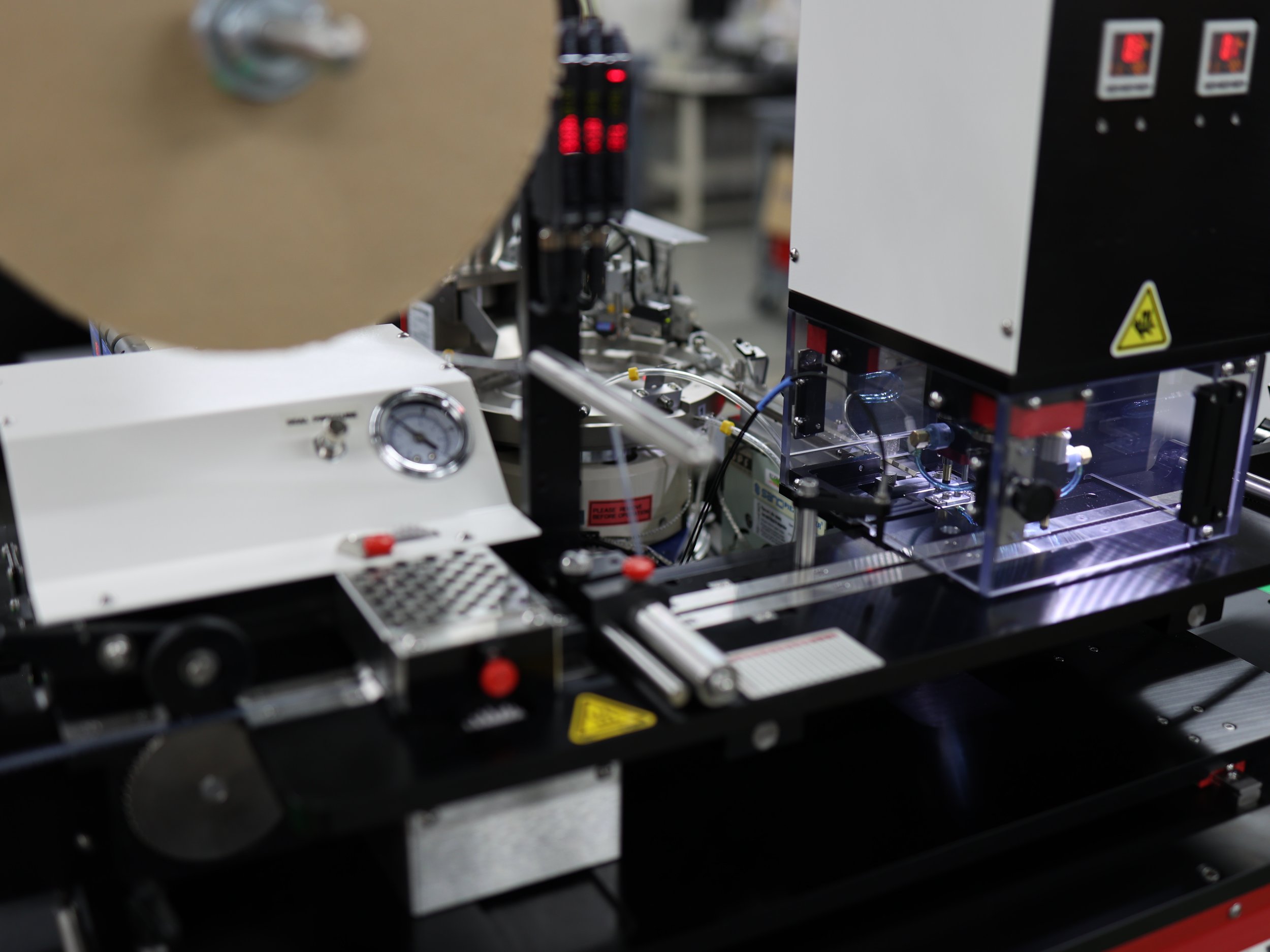

TM-700

The TM-700 is a high-speed rotary system capable of taping small devices up to 18,000 UPH. It’s easily configurable design allows for up to five independent processes prior to reject binning and tape output. With its servo-controlled vertical motion, the TM-700 is able to run delicate parts through multiple processes with precise acceleration and deceleration. The TM-700 can be converted between different input media and part sizes as determined by configuration.

-

Tape Output adjustable sizes 8-24mm

Part size 0402 and greater (smaller sizes possible, contact V-TEK)

Minimum part sizes: 1mm x 1mm or 0402

Dimensions: H 82" (208cm) x W 84" (213cm) x D 34" (86cm), Weight 1200lbs (545 kg)

Power required: 210-240 VAC, 47/63 Hz, Max current draw 8 amps, Air 15 SCFM at 80 PSI

Up to 18,000 UPH (limited by input device and processes required prior to placement in output device)

-

Input bowl (CCW or CW) can be converted quickly

Universal tube feeder input

Available 2D in-pocket inspection prior to seal

Heat or PSA seal

-

Test (multiple site capable around turret)

Vision inspection (5-sided, 3D)

Lasermarking

Reject sorting

As an equipment manufacturer, V-TEK collaborates with major tape and reel companies to ensure their products are compatible with ours. As part of a refined supply chain, V-TEK is your single source of fully qualified consumable products.